Descriptive Terminology

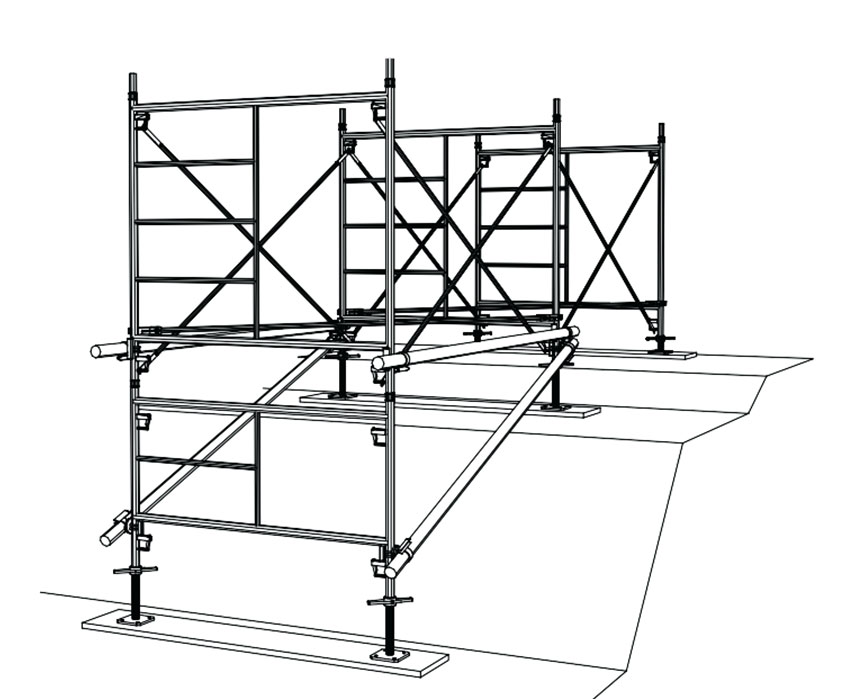

Access Frame Scaffold

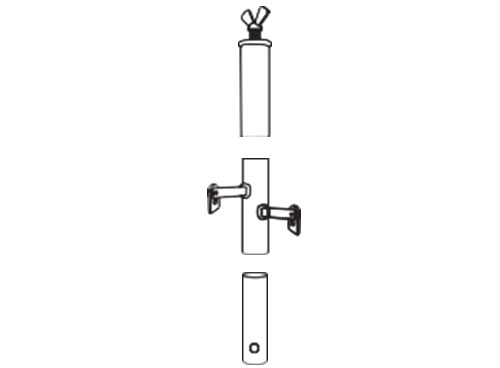

Standard frames

Frames are made up in various widths and heights and for various load capacities. The most common width of frame is 1.5 m (5 ft .). However, there are frames 1.2 m (4 ft.) and 1.0 m (3 ft.) wide in daily use. The height of frames can vary from 1.0 m (3 ft.) to 6.0 m ( 20 ft.). Three types of standard frames are shown below.

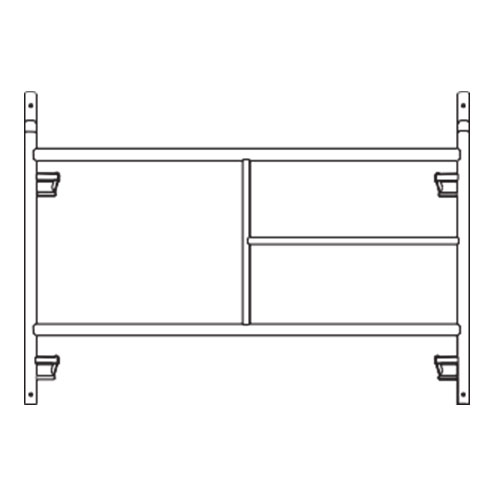

Standard half or bench frame

This frame is 1.0 m (3 ft.) high x 1.5 m (5 ft.) wide. It is often used at the base of a scaffold especially with arch frames when height or heavy loading is a factor. It is also used as a make up when the ground level drops away in excess of 1.0 m (3 ft.).

Standard end frame

This frame is 1.5 x 1.5 m (5 x 5 ft.) and is often used to form rolling scaffolds. It is also used with side brackets or when the top working lift only is required.

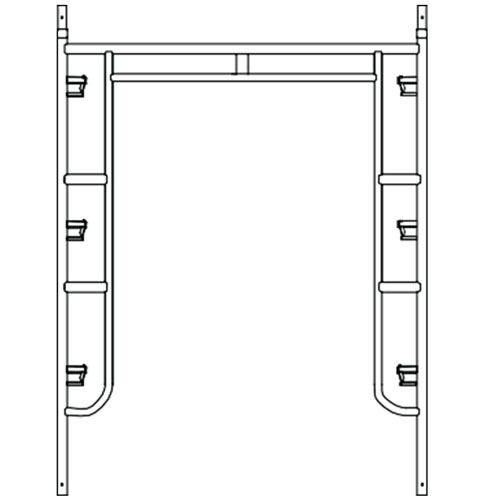

Standard arch or walk-through frame

This frame may vary in width but is generally 2.0 m (6 ft. 6 in.) high. It is used where a multi- trade application or more than one working level is required. It is also popular with bricklayers when used with side brackets.

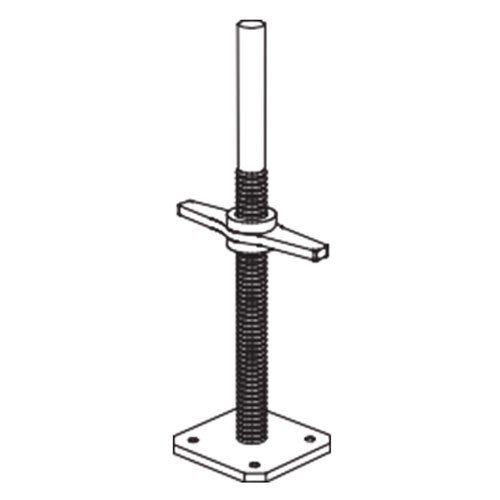

Adjustable base plate

Installed in the bottom of the legs of frames and usually seated on a wood sill. The plate can be adjusted for various ground conditions (as specified by the manufacturer).

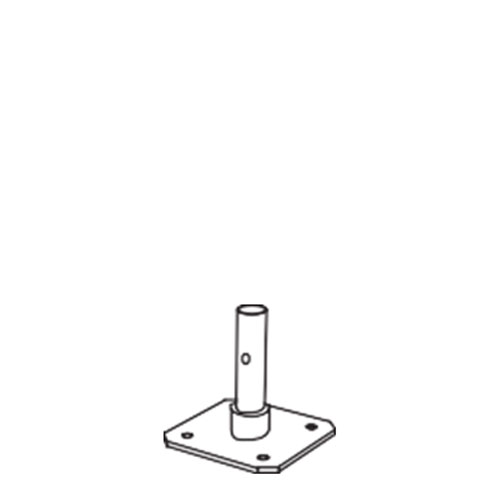

Plain base plate

Installed in the bottom of the legs of frames and usually seated on a wood sill. The plate spreads the downward load so the leg does not punch through the sill.

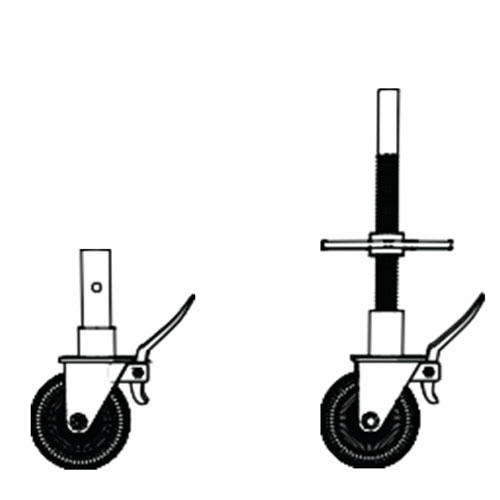

Caster and caster with screw jack

Placed in the bottom of the frame leg to form a rolling scaffold. Several sizes are available and load capacities can vary. The manufacturer’s or the supplier’s instructions must be followed, especially with regard to adjustments. All casters must have working brakes. Casters must not be allowed to fall away from the frame leg.

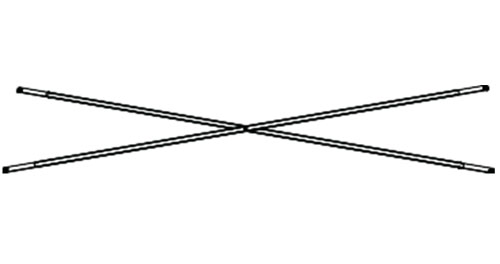

Cross-brace

The dimension is generally determined by the various bay size lengths, from 1.0 m (3 ft.) to a maximum of 3.0 m (10 ft.). They are used in pairs to join frames together.

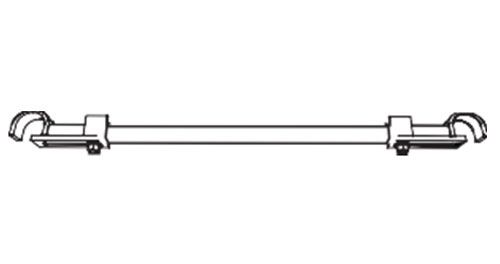

Plan brace or gooser bar

Installed at the bottom of a rolling scaffold or a free-standing tower to prevent the structure from racking (going out of square). It may also be required at other heights and spacing within the scaffold structure as specified by the manufacturer or supplier.

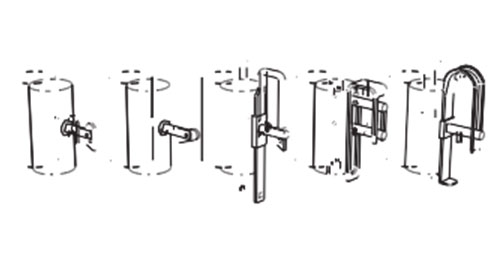

Brace lock

The attachment on the frame leg for installing the cross-brace to the frame.

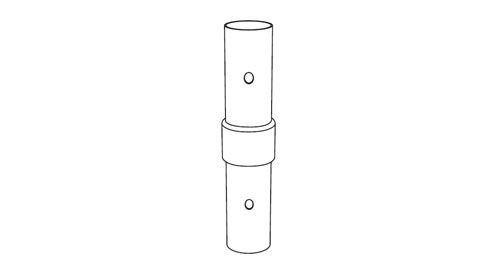

Vertical coupling pin

Inserted in the top of the frame legs to allow for the stacking of frames, quite often fixed to the frame.

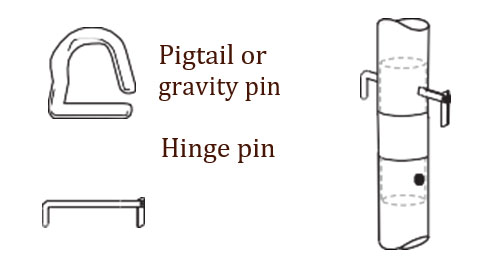

Lock pin

Placed through the frame leg and coupling pin to prevent the frames separating.

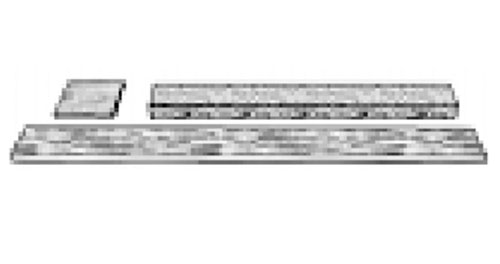

Sill or mud sill

Usually made out of wood. Placed under the base plates, the sill spreads the downward load from the scaffold and anything placed on the scaffold (such as materials and workers). The sill can vary in size, from a piece of 12 x 12 x 3/4 in. plywood to a 9 in. x 6 in. x 8 ft. rail tie, depending on the ground conditions and the anticipated loads.

Toeboard

Usually made from nominal 1 x 4 in. lumber and installed on all the outer edges of the platform where there is a possibility of materials or tools rolling off the platform. The top of the toeboard must be at least 10 cm (4 in.) above the platform.

Deck or plank

Forms the working or loading platform for persons and materials. The load capacity is determined by the unsupported span of the plank or deck. For manufactured planks or decks, check specifications for loading.

Guardrail post

Fixed to the top frame of a scaffold structure. Generally two types are available, intermediate and corner post

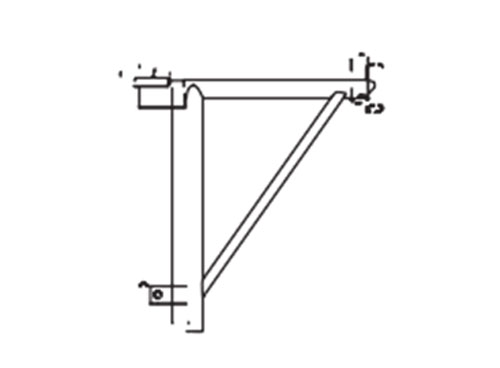

Side or end bracket

Normally a two-plank or one-deck wide bracket. It is hooked onto the face of the scaffold, either to increase the platform width or to create an intermediate platform. It allows workers such as bricklayers unrestricted access to the working surface.

Outrigger bracket

Fixed to the base of a free- standing tower or a rolling scaffold to increase the base dimension. It prevents overturning in accordance with the 3 to 1 rule applicable to free-standing towers and rolling scaffolds. It can be used with an adjustable base plate or a caster with screw jack.

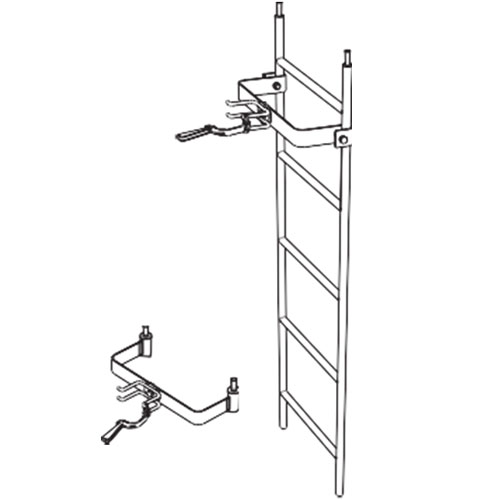

Vertical ladder and bracket

Purpose-made ladder system for use with frame scaffolding.

Note about access: Some frames (except arch frames) are designed as ladder- climbing frames. On both vertical ladders and ladder-climbing frames, the rungs or intermediate crossbars must be spaced at 30 cm (12 in.) on centre.

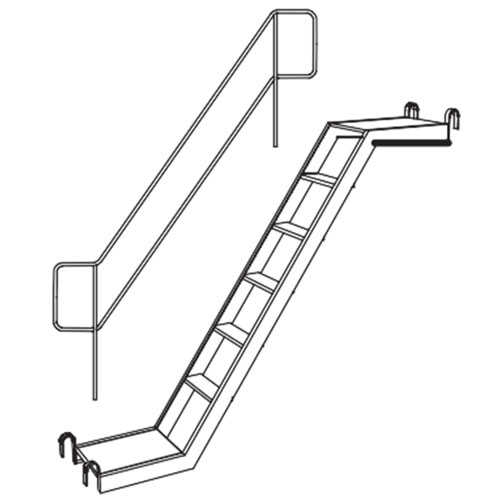

Stair section and handrail

Incorporated into a frame structure as a means of access.

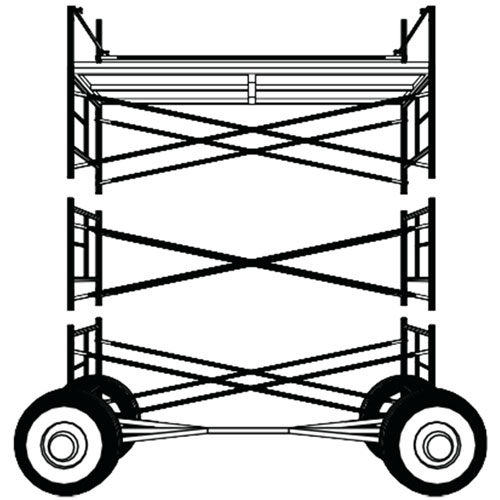

Farm wagon

A unit with pneumatic tires to form the base of a rolling scaffold. It can be towed manually or mechanically. Make sure that brakes are installed, as well as base jacks to pick up the load in case of a flat tire.